A very critical component in the field of logistics warehousing and cargo handling - forklift brakes. When you hear the word "brake", you may think, "Oh, isn't this thing just for parking?" In fact, it is not entirely true. Forklift brakes not only play a role when parking, but its performance is also directly related to your operating safety. Imagine if the forklift suddenly failed to brake in the busy work, it would be a big trouble. Don't worry, this article will unveil the mystery of forklift brakes for you, talk about its uses, selling points, purchase methods and maintenance precautions, and help you better use this key equipment.

The main task of the forklift brake is to allow the forklift to stop steadily when it needs to slow down or stop.

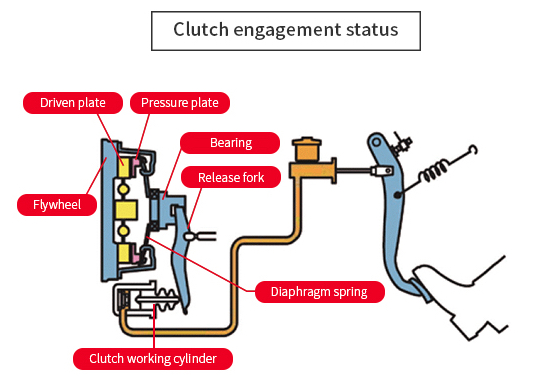

Its working principle is simple: the kinetic energy of the forklift is converted into heat energy through friction, thereby reducing the speed or stopping the forklift completely. It can be said that the forklift brake is like the brake when you drive, ensuring that you can accurately control the speed when handling goods, respond to emergencies in time, and avoid accidents. Moreover, forklift brakes do not only work on the ground.

If the forklift you are operating is an electric forklift, the braking system also involves some special electronic control technologies, such as the regenerative braking system, which can recover and store the energy generated during braking to improve the energy efficiency of the forklift.

01 Safe and reliable:

High-quality forklift brakes can maintain stable braking force in various situations. Whether it is under heavy load or on a ramp, it can ensure good braking effect of the forklift, allowing you to operate with confidence. Especially in the warehouse environment where there are shelves on all sides, stable braking effect is crucial. It can prevent the forklift from losing control and protect your work environment and the safety of your colleagues.

02 Sensitive response:

High-quality brakes react very quickly and can start immediately in an emergency, shorten the braking distance, and allow you to stop quickly at critical moments to avoid collisions. This is especially suitable for high-intensity and high-frequency work scenarios, such as busy sorting centers or warehouses next to production lines. .

03 Strong durability:

Brakes made of wear-resistant materials have a long service life, reduce replacement frequency, and reduce maintenance costs. In other words, you save a lot of money and a lot of trouble. Moreover, durable brakes can also reduce equipment downtime and improve overall operating efficiency. Time-saving and labor-saving, this is the gospel of every warehouse manager!

04 Easy to maintain:

Well-designed brakes make inspection and maintenance simple and quick, saving your precious time and energy, and making daily maintenance easy. Most modern forklift brakes are equipped with automatic diagnostic systems, which can provide early warnings when problems occur, avoiding the trouble caused by sudden failures.

Matters needing attention during maintenance

01 Use professional tools

When maintaining brakes, be sure to use the right tools. Using the wrong tools is like using chopsticks to tighten screws, which may make a mess and may also damage parts. Make sure you have the right wrenches, screwdrivers and other tools on hand, and follow the standard maintenance process when operating.

02 Follow operating procedures

Be sure to follow the maintenance manual provided by the manufacturer, and never change the structure or settings of the brake at will. It's like you have to follow a recipe when cooking, and adding seasonings randomly will be miserable. The manufacturer's manual provides the maintenance method that best suits your equipment. Following these instructions can avoid unnecessary failures and losses.

03 Pay attention to personal safety:

When inspecting and maintaining the brakes, remember to wear personal protective equipment, such as gloves, goggles, etc. Safety first, don't let yourself get hurt during maintenance. Be careful when using tools, ensure a clean working environment, and avoid putting your hands or body close to rotating parts.

04 Avoid environmental pollution:

The old brake fluid and worn parts that have been replaced should be properly handled to avoid pollution to the environment. When disposing of these wastes, pay attention to classification just like throwing away garbage, and don't let them become a hidden danger to the environment. There are special waste disposal points in many places where these wastes can be sent for disposal.

05 Regular training:

Regular training should be provided for operators and maintenance personnel to ensure that they are aware of the latest maintenance techniques and safety regulations. Regular training can not only improve the team's skill level, but also improve the service life of the equipment and overall work efficiency.

In short, forklift brakes are an important component to ensure the safe operation of forklifts, and their performance directly affects the efficiency and safety of operations. Understanding the use, selling points, maintenance methods and maintenance precautions of brakes can help forklift operators and managers better use and maintain this equipment.