Water pumps are essential components in various industries, from residential water systems to industrial applications, and their efficiency and performance have a direct impact on operational costs and sustainability. Over the years, pump technology has evolved significantly, with DC (Direct Current) pumps and AC (Alternating Current) pumps being the two primary types in the market. While AC pumps have traditionally been the standard due to their stability and cost-effectiveness, DC pumps have gained significant traction in recent years thanks to advancements in energy efficiency, compact design, and precise control features. Market trends reflect a growing demand for energy-efficient and environmentally friendly solutions, driven by both consumer preferences and stringent environmental policies globally. As businesses and governments alike focus on reducing carbon footprints and enhancing the efficiency of energy use, DC pumps are expected to play an increasingly important role in sectors such as residential water heating, electric vehicles, and renewable energy systems. This shift in demand is further influenced by historical advancements in motor technology, changing user needs for more versatile and cost-effective solutions, and the ongoing development of policies favoring sustainable technologies.

1. Working Principle

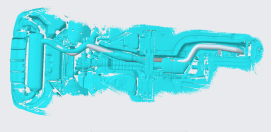

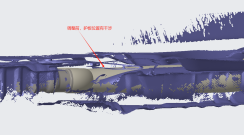

· DC Pumps: These pumps use a DC power supply and control the motor speed through an electronic controller, providing high-speed adjustment accuracy. DC pumps typically use permanent magnet motors, making them compact and efficient.

· AC Pumps: These pumps use an AC power supply, with the motor generating torque from alternating current. AC pumps generally require more complex control systems and often need frequency converters to adjust the speed.

2. Efficiency and Energy Consumption

· DC Pumps: DC pumps are generally more energy-efficient because they use permanent magnet motors and can adjust the speed according to the load. As a result, they are more energy-efficient at lower loads compared to AC pumps.

· AC Pumps: AC pumps typically have lower efficiency, especially under varying loads, leading to higher energy consumption.

3. Speed Control

· DC Pumps: DC pumps offer excellent speed control by adjusting voltage or current, making them highly flexible for applications that require frequent flow rate adjustments.

· AC Pumps: Speed control in AC pumps is more complex and typically requires additional equipment like variable frequency drives (VFDs), making them less flexible and precise compared to DC pumps.

4. Lifespan and Maintenance

· DC Pumps: DC motors usually is brushesless motor, so maintenance is low, and the lifespan is relatively long.

· AC Pumps: AC motors often require periodic maintenance, such as replacing brushes, and may have a shorter lifespan due to internal wear.

5. Cost

· DC Pumps: DC pumps are generally more expensive to manufacture due to their advanced motor technology, but they can save energy and maintenance costs in the long run.

· AC Pumps: AC pumps are less expensive to manufacture but tend to incur higher operational and maintenance costs over time.

6. Noise

· DC Pumps (Brushless DC Pumps): Low Noise Levels, One of the standout features of DC pumps, particularly brushless DC pumps (BLDC), is their ultra-quiet operation. The brushless design reduces mechanical wear and tear, leading to less vibration and noise generation. Additionally, the precise electronic control used to adjust the speed of DC pumps contributes to smoother and quieter operation compared to AC pumps.

· AC Pumps: Higher Noise Levels: AC pumps tend to generate more noise due to their electromagnetic induction and the presence of brushes in traditional AC motors (in some older models). The rotating magnetic field and mechanical components can result in vibrations that contribute to higher noise levels, especially when the pump operates at higher speeds or under varying load conditions.

7. Market Applications

· DC Pumps: Due to their higher efficiency, precise speed control, and compact size, DC pumps are widely used in:

o Water circulation systems (e.g., household water heaters, HVAC systems, solar water pumps)

o Automotive cooling systems (e.g., electric vehicle cooling pumps, air conditioning pumps)

o Smart home devices (e.g., smart toilets, electronic heating systems)

With the growing demand for energy efficiency and sustainability, DC pumps are gaining traction, especially in the fields of home automation, electric vehicles, and renewable energy systems.

· AC Pumps: AC pumps are commonly used in traditional large-scale industrial systems, commercial HVAC systems, and long-term, continuous operations. They are reliable and stable, especially for high-flow or high-power applications.

8. Future Market Trends

· DC Pumps Market Trend:

o High Growth Potential: DC pumps are expected to see continued growth in applications such as water circulation, air conditioning, and electric vehicles due to their energy efficiency and performance.

o Smart Integration: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in DC pumps will enable remote monitoring, intelligent adjustment, and predictive maintenance, further increasing their market appeal.

o Miniaturization and Integration: With advancements in technology, DC pumps will become more compact and integrated, suitable for use in smaller devices and systems.

· AC Pumps Market Trend:

o Stable Demand: AC pumps will continue to dominate in traditional industries where high flow rates and continuous operation are essential, such as large industrial systems and commercial HVAC.

o Transition to Energy Efficiency: As energy efficiency becomes a priority globally, some high-energy consumption AC pumps will be gradually replaced by more efficient DC pumps, especially in smaller systems.

Summary

DC pumps offer superior efficiency, energy savings, speed control, and low maintenance costs, making them ideal for applications in smart homes, water circulation, and electric vehicles. AC pumps, on the other hand, remain dominant in traditional large-scale systems, where they provide reliable, continuous operation. The future market will likely favor more energy-efficient, smart, and eco-friendly solutions, where DC pumps will continue to gain ground due to their advantages in energy efficiency and intelligent capabilities.