From September 20 to 23, 2024, the 2024 World Manufacturing Conference was held in Hefei, Anhui, China with the theme of "Smart Manufacturing World, Creating a Better Future".

The World Manufacturing Conference is a highly influential event that brings together global industry leaders, innovators, and experts to exchange ideas and explore the latest advancements in manufacturing. Its successful organization has had a profound impact on various sectors, including the automotive parts industry. In this article, we will examine the transformative effects of the World Manufacturing Conference on the automotive parts sector.

Collaboration and Networking Opportunities:

The World Manufacturing Conference provides a unique platform for automotive parts manufacturers to engage in collaboration and networking opportunities with industry peers, policymakers, and technology providers. These interactions foster knowledge sharing, strategic partnerships, and business alliances. By leveraging these connections, automotive parts companies can expand their reach, gain valuable insights, and forge mutually beneficial relationships that drive growth and innovation within the industry.

Technological Advancements:

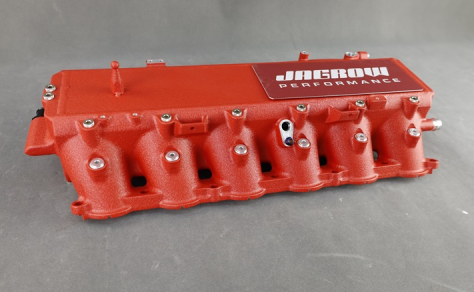

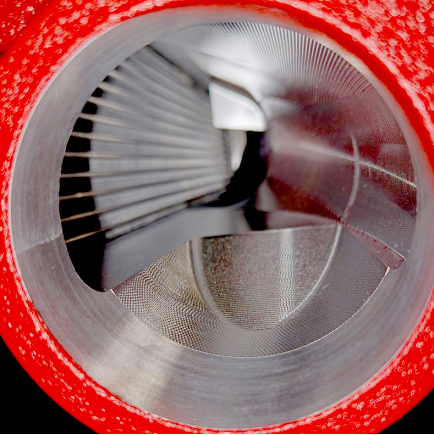

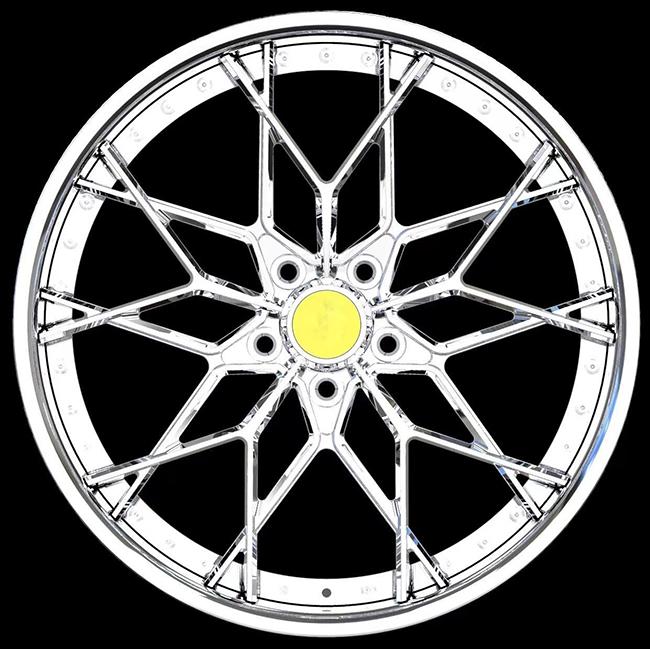

The conference showcases the latest technological advancements that have the potential to revolutionize the automotive parts industry. Manufacturers can explore cutting-edge technologies such as additive manufacturing, robotics, artificial intelligence, and Internet of Things (IoT) solutions. These disruptive technologies can significantly enhance efficiency, productivity, and product quality in the production of automotive parts. The exposure to these innovations encourages manufacturers to adopt advanced manufacturing techniques, staying at the forefront of industry trends and gaining a competitive edge.

Market Intelligence and Industry Trends:

Attending the World Manufacturing Conference allows automotive parts manufacturers to gain valuable market intelligence and insights into emerging industry trends. Keynote speeches, panel discussions, and presentations by industry leaders provide a comprehensive overview of the latest market dynamics, consumer preferences, regulatory changes, and global trade patterns. Armed with this knowledge, companies can make informed decisions, develop targeted strategies, and align their business operations to meet evolving customer demands effectively.

Supply Chain Optimization:

Efficient and robust supply chain management is crucial for the automotive parts industry. The World Manufacturing Conference facilitates discussions on best practices for supply chain optimization, including just-in-time manufacturing, lean principles, and intelligent logistics solutions. By implementing these strategies, manufacturers can reduce lead times, minimize inventory costs, ensure timely delivery of components, and enhance overall operational efficiency. The insights gained from the conference enable automotive parts companies to build agile and resilient supply chains.

Sustainable Manufacturing Initiatives:

The World Manufacturing Conference emphasizes the importance of sustainable manufacturing practices within the automotive parts industry. Topics such as renewable energy integration, energy-efficient processes, waste reduction, and circular economy principles are discussed thoroughly. As a result, manufacturers gain a deeper understanding of environmental stewardship and are inspired to adopt sustainable practices. By embracing eco-friendly manufacturing processes, automotive parts companies can reduce their carbon footprint, enhance brand reputation, and meet the growing demand for sustainable products.

The successful organization of the World Manufacturing Conference has had a significant impact on the automotive parts industry. It has created avenues for collaboration, stimulated technological advancements, provided market intelligence, optimized supply chains, and encouraged sustainable manufacturing practices. By participating in this influential gathering, automotive parts manufacturers can stay ahead of the curve, adapt to industry changes, and thrive in a competitive marketplace.