Ceramic Coating in Exhaust Systems

Introduction:

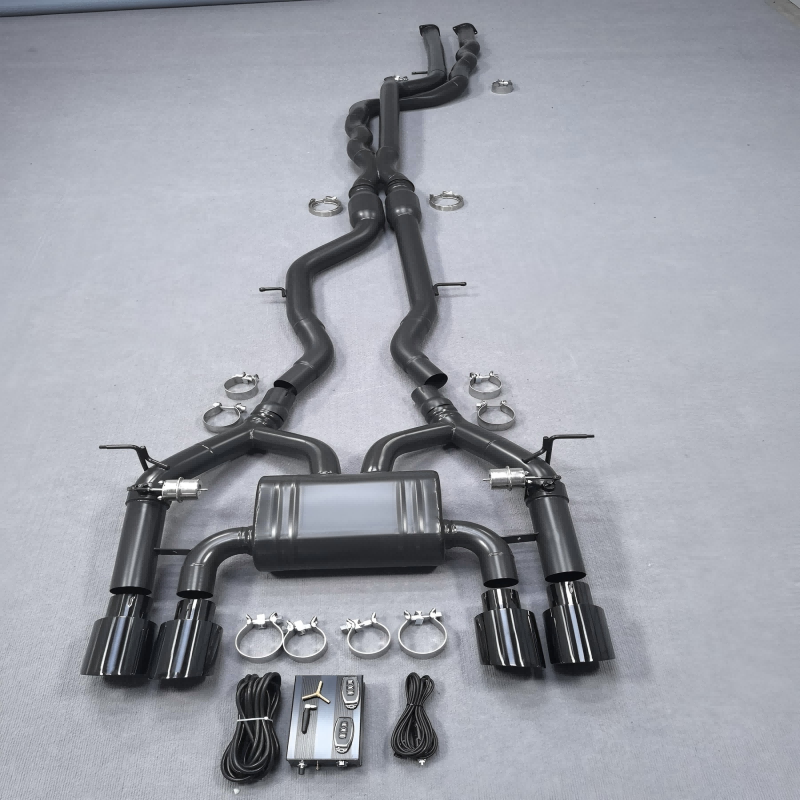

The roar of a car's engine is not just about power—it's also about performance and aesthetics. One critical aspect of achieving that perfect balance is the exhaust system, and within that, the use of ceramic coating on exhaust components. In this blog post, we'll explore the process of ceramic firing for automotive exhaust systems and why it matters.

The Science Behind Ceramic Coating:

Ceramic coating is a process that involves applying a thin layer of ceramic material to a surface, transforming it into a high-performance component. In the context of automotive exhaust systems, this process is used to enhance durability, heat resistance, and longevity of the exhaust components.

Color options:

Currently the main colors are black, silver, bronze, or if you want more sets, we can customize the color for you, but there are MOQ requirements, please contact me for more details.

The Ceramic Firing Process for Exhaust Systems:

1. Preparation: The exhaust components, such as manifolds or mufflers, are cleaned and prepared to ensure a smooth surface for the ceramic coating.

2. Coating Application: A ceramic coating is applied to the exhaust components. This can be done through various methods, including thermal spray or dip coating.

3. Curing: The coated components are then cured to set the ceramic layer, preparing them for the high-temperature firing process.

4. Firing: The components are placed in a kiln and heated to extremely high temperatures, typically around 1400°C to 1600°C (2552°F to 2912°F). This step is crucial as it hardens the ceramic coating, creating a robust and durable surface.

5. Cooling and Inspection: After the firing process, the components are slowly cooled to room temperature to avoid thermal shock. They are then inspected for any defects or inconsistencies in the ceramic coating.

Benefits of Ceramic Coating in Exhaust Systems:

- Heat Resistance: Exhaust systems operate under extreme heat. Ceramic coatings can withstand these temperatures, protecting the underlying metal from heat degradation.

- Corrosion Protection: Ceramic coatings provide a barrier against corrosive elements, such as water, salt, and chemicals, that can damage the exhaust components over time.

- Enhanced Performance: The smooth surface of ceramic coatings can reduce exhaust gas friction, leading to improved flow and potentially increasing horsepower and fuel efficiency.

- Aesthetic Appeal: Ceramic coatings can also provide a sleek, high-quality finish to the exhaust components, enhancing the vehicle's appearance.

Case Studies and Real-World Applications:

We've seen firsthand the benefits of ceramic coating in our own product line. For instance, our ceramic-coated exhaust have shown significant improvements in heat dissipation and durability, leading to happier customers.

Ceramic coating is more than just a trend in the automotive industry—it's a necessity for those seeking to push the limits of performance and style. As technology advances, we can expect to see even more innovative uses of ceramic coatings in exhaust systems and beyond. Here at Jagrow, we're proud to offer ceramic-coated exhaust components that stand up to the rigors of the road and look great doing it.

Pls feel free to contact me if you have any requirements,good products will send to you.