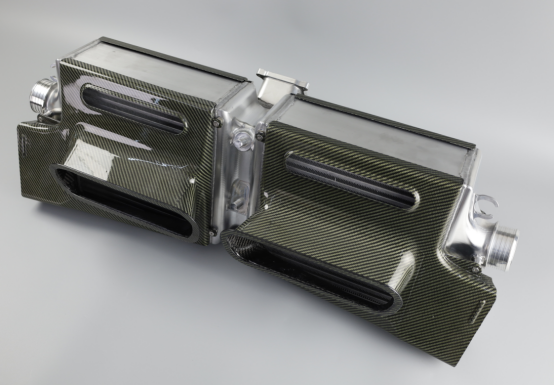

Porsche 992 intercooler with CNC tank and carbon fiber air guide hood

Recently we developed below new version intercooler with CNC tanks and carbon fiber air guide hood for Porsche 911 992.

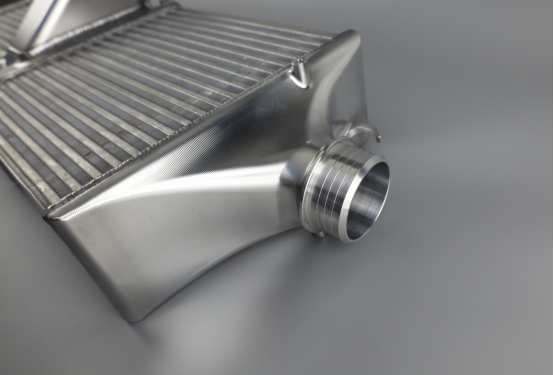

As you can see,it has beautiful CNC tanks which is popular in the market due to below unique advantages.

High Precision: CNC (Computerized Numerical Control) machining technology ensures a high level of precision in the manufacturing of the intercooler tanks. This precision allows for optimal fit and function, enhancing the overall performance of the intercooler.

Efficient Heat Exchange: The precisely manufactured CNC header ensures maximum contact surface area with the coolant, thus improving heat exchange efficiency. This helps reduce engine intake temperatures, enhancing engine power and efficiency.

Durability: CNC machining produces headers that are structurally strong and durable. This ensures reliability under high-pressure and high-temperature conditions, minimizing the risk of failures.

Customizability: The flexibility of CNC machining allows for the creation of customized headers that fit specific engine and intercooler configurations. This customization ensures optimal performance for a given application.

Consistent Quality: CNC machining processes are highly repeatable, resulting in consistently high-quality headers. This consistency ensures reliable performance over time and reduces the need for frequent replacements or repairs.

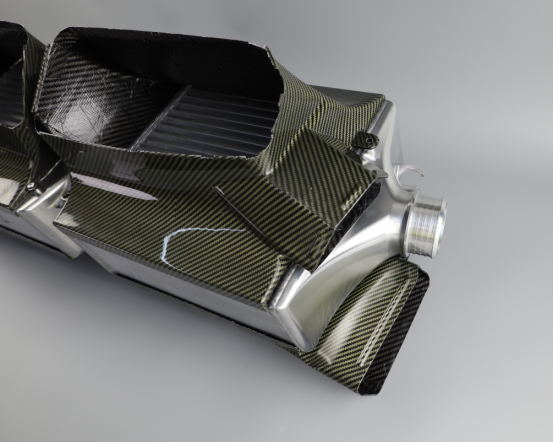

In advance,the intercooler also have the carbon fiber air guide hood which is a significant improvement in the aftermarket tuning market.

Lightweight: Carbon fiber is known for its exceptional strength-to-weight ratio. Designing the air guide hood of the intercooler with carbon fiber reduces its overall weight while maintaining structural integrity. This lightweight design helps improve vehicle performance by reducing the overall weight of the intercooler system.

Improved Aerodynamics: Carbon fiber can be molded into complex shapes and aerodynamic profiles. By designing the air guide hood with carbon fiber, it is possible to create streamlined surfaces and optimized airflow channels. This promotes efficient air intake and reduces turbulence, enhancing the intercooler's cooling efficiency.

Heat Resistance: Carbon fiber exhibits excellent heat resistance properties. It can withstand high temperatures without deforming or losing its structural integrity. This makes it an ideal material choice for the air guide hood of the intercooler, which is exposed to the hot airflow from the turbocharger.

Aesthetic Appeal: Carbon fiber has a visually appealing, high-end appearance. By incorporating a carbon fiber air guide hood into the intercooler design, it adds a touch of luxury and sportiness to the overall aesthetics of the vehicle, enhancing its visual appeal.

Customizability: Carbon fiber can be easily molded and shaped to meet specific design requirements. This allows for customization of the air guide hood, enabling designers to tailor it to the specific dimensions and airflow requirements of the intercooler system.

These design highlights contribute to enhanced performance, durability, visual appeal, and overall efficiency of the respective components.

Jagrow committed to the new design of the market and maximize the customer to solve the modification market one-stop service.Feel free to contact us if you have any customized requirements.